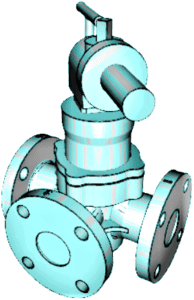

3 way plug valve

3 Way Plug Valve

While each valve has similar roles, it’s their unique features that distinguish between them. In this article, we will have a closer look at a special type of valve, known as 3-Way Plug Valve.

These valves are designed to handle different types of fluids which may be clean or dirty. Before we go deep about the 3-way Plug Valve, let us first understand what a Plug way is?

What Is A 3-Way Plug Valve?

The most popular kinds of plug valves are two-way and three-way plug valves. The three-way plug valves are particularly helpful since they may be configured in ways that simplify gas and fluid flow control.

The 3-way plug valve comprises of a three-way valve body, disc, spring seat, and lever, etc. The opening, shutting, correction, and distribution of the pipeline media may freely be controlled by turning the plug. Three-way valves are often able to address more complicated flow control requirements than two-way valves. This makes it helpful for many different processes.

For example, one kind of plug valve arrangement can be used to combine purified water from one source with juice from another source. An alternative three-way valve design may redirect fuel from one tank to another tank and, if necessary, may also completely discontinue the fuel flow.

How Does A 3-Way Plug Valve Work?

Plug valves may have multi-ports valves like three, four, or five. The three-way plug valve is the most popular multi-port plug valve.

Three ports valve is attached to pipe or tubing that provides a three-way plug valve for gas or fluid to flow through them. These ports are generally defined as one inlet and two outlet ports or one outlet or two inlet ports in the function of the valve’s flow direction.

A three-way plug valve is quite common because it is an inexpensive and easy means of providing a single valve body with shut-off and flow control. These valves control the flow of tube control by combining the piping setup, the plug valve manual rotation, and the plug valve flow path.

The flow can be regulated using the proper type of valve and installation in ways that satisfy one or many process criteria, that includes,

- Shutting the flow completely.

- Mixing of flow from two different pipe inlet to one outlet.

- Diverting the flow from one pipe to another.

- Dividing the flow from one pipe to different pipes.

- It can also block flow in one direction while allowing the flow to continue in another direction.

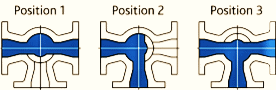

There is a basic but important internal difference in design that influences what a three-way valve can achieve. The flow or port shape pattern within the valve through the plug is this significant design distinction.

Three-way valves that generally have a third port at a right angle from the inlet are popular. The closed element is utilized to divert or combine the flow with the three-way design.

- Diverting Flow-Flow entering the pier and moving through the pin to one of the two exits.

- Diverting flow If the plug is shifted to 90°, the flow to the other outlet is channel. The flow may be split into two outputs at the middle position.

- Flow combines — Flow from two entrances to one output.

Classification Of 3-Way Plug Valve

These valves can be broadly classified into the following categories:

- Thread End Stainless Steel 3-Way Plug Valve

- Thread End Bronze 3-Way Plug Valve

- Flanged End Stainless steel 3-way plug Valve

- Flanged End Cast Steel 3-Way Plug Valve

- Flange End Bronze 3-Way Plug Valve

- Jacket 3-Way Plug Valve

Features And Benefit Of 3-Way Plug Valve

The primary characteristic of the 3-way plug valve is that it can easily adapt to the multi-channel construction, which may be separated in a three-way, four-way, etc. Multi-channel valves improve the design of pipe systems, minimize the use of the valve and some necessary connection attachments on the machines.

Plug 3-way Valve ensures safe and effective repair without any process disruptions of redundant pressure relief systems. It is done by the smooth functioning of the valve, making it possible to switch from the primary system to the secondary system while giving the isolated system a positive shut-off.

To switch the systems through a single valve, just a single connection in a pressure vessel is needed so that the system may switch quickly and can avoid costly depressurizing. The valve’s basic port setup always delivers flow between the base port and one of the side ports.

Application Of 3-Way Plug Valve

3-Way Plug Valves are intended to manage a variety of liquids, including clean and dirty liquids, viscous and corrosive solutions, as well as sludge, abrasive and fibrous slurries. They can also handle clean and dirty corrosive gases.

They are used in a wide variety of applications, such as

- Flow diversion of water

- Wastewater

- Sewage and Biogas applications

- Chemical & Petrochemical

- Pulp & Paper

- Mining Power and other process industries.

- It can also be used for a combination of flow from different sources.

Summary

Understanding the fundamental design possibilities for three-way plug valves makes it easier to select the correct valve type as per its design and applications.

If you’re reading this, we’d like to thank you and hope that you find the information shared in the article helpful.

Please write to us in the comment section or email us if you have questions, comments, or suggestions about the 3-way plug valve. As a professional 3 way plug valve manufacturer, we will be happy to provide you any kind of assistance.