PTFE Lined Plug Valve

PTFE Lined Plug Valve

NTGD is professional PTFE lined plug valve manufacturer, Don’t hesitate to contact us if you have any inquiry.

What is PTFE-lined plug valve?

This is a plug valve in which the interior parts are covered with PTFE material. PTFE means Polytetrafluoroethylene and it is a thermoplastic polymer that is characterized by mainly a slippery surface, high chemical and weathering resistance, and high melting point. This material is very stable at high temperatures like 250 oC which makes the valve suitable for use at such high temperatures. PTFE lined plug valve manufacturers produce this valve to operate using a handwheel/hand lever or by using actuators. This type of valve is in the class of quarter turn valves. This means that the valve needs a quarter turn of the handle or actuator and then it will either start or stop depending on the direction of rotation. This characteristic makes the valve very fast and simple to operate. PTFE-lined plug valves can be used in various applications such as foods, oil and gas, water supply, and chemical processing among others.

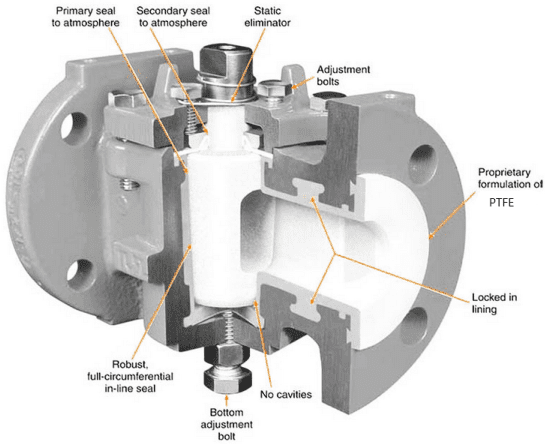

Components of a PTFE-lined plug valve

Handle

The handle in a PTFE-lined plug valve is the part where one applies torque to open or close fluid flow. The handle is used in manually operated valves. For an automatic valve, an actuator is used. The actuator is tasked with providing the torque that the valve needs to open or close the fluid flow.

Stem

This is the component that transmits the torque applied on the handle by the operator to the plug. PTFE lined plug valve manufacturer design the stem with threads that help the stem to rotate.

Plug

The plug is the component that helps to open or close the fluid flow. It gets the power to operate from the valve stem. It is connected to the stem through its top end. The plug has a port or more than one port which when aligned with the valve ports allows fluid to flow through the valve.

Valve body

The valve body is used to house internal parts of the PTFE-lined plug valve such as the plug and seat. This component is usually made of very strong metallic materials such as carbon steel and stainless steel among others. This ensures the valve body remains very strong against high pressure as well as impact damage. The valve body also contains the inlet and exit ports of the valve that are connected to the pipeline.

Body cover

The body cover is placed on top of the valve body and as the name suggests, it helps to cover the body’s top part to prevent any fluid leakage. It is through the body cover that the valve can be opened for inspection and cleaning while it is still connected to the pipe. The body cover and valve body are made of the same metallic material.

Gaskets

These components are used to prevent fluid leakage between the body cover and the valve body as well as between the pipe and the valve body connection. Bolts and nuts as well as screw threads are used to tighten the connection where the gasket is mounted.

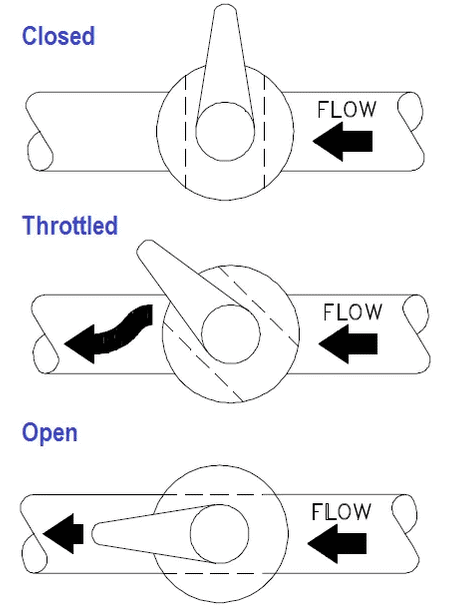

How does a PTFE-lined plug valve work?

A PTFE-lined plug valve operates by rotating the valve plug for only a quarter turn. For the plug to make the quarter turn rotation, torque has to be applied on the handwheel or from the actuator. To start the valve, the handwheel is rotated for 90o degrees in the clockwise direction. This rotation from the handwheel is transmitted through the valve stem to the valve plug. This forces the plug to rotate for 90o degrees forcing its port to align straight to the valve port. As such, fluid starts flowing through the valve. To stop the valve, the handle is rotated in the counterclockwise direction for another quarter turn. This rotary motion is again transmitted to the valve plug via the stem. Due to this rotation, the plug rotates for 90o degrees becoming perpendicular to the valve port. This ensures the fluid is blocked and thus the valve is stopped.

PTFE-lined plug valve manufacturers design this valve so that by rotating the plug slightly by around 45o degrees, throttling flow can be achieved.

Types of PTFE-lined plug valves

Three-way PTFE-lined plug valve

This is a PTFE-lined plug valve with three ports. This type of valve is used in various applications that involve fluid mixing and fluid diversion. For fluid mixing, the fluid streams from two valve ports are mixed inside the valve body. After mixing, the fluid leaves the valve via the exit port as one fluid stream. When used to divert fluid flow, one fluid stream enters the valve and its direction of flow is changed inside the valve body to an angle of 90o degrees. This type of valve is very economical since it can serve the functions of three or two gate valves thus reducing the cost of the piping system.

Figure: Three-way PTFE-lined plug valve.

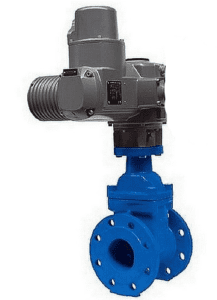

Electric PTFE-lined plug valve

This is the type of PTFE-lined plug valve that is operated by use of an electric actuator. This type of actuator uses electricity to operate. The actuator is placed on top of the body cover. The actuator is connected to the valve stem to help transmit power to the valve plug. The actuator has an electric motor that converts electrical energy to mechanical energy. This type of valve is very versatile as it can work in all areas of valve applications provided there is electricity. The valve is also automated such that it can open and close the fluid flow independently of a valve operator.

Figure: Electric PTFE-lined plug valve.

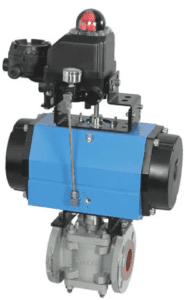

Pneumatic PTFE-lined plug valve

This is the type of PTFE-lined plug valve operated by use of a pneumatic actuator. This actuator operates by use of compressed gas/air. The actuator consists of one or two chambers where compression of air takes place. The compressed air acts on a piston. This forces the piston to rotate creating mechanical energy. This mechanical energy (torque) is used to operate the valve stem and thus the valve plug. PTFE-lined plug valve manufacturers recommend use of this valve in applications that have high demands of hygiene like foods and pharmaceuticals since the compressed air/gas used can be filtered. As such, it helps remove any impurities that may cause contamination to the product being manufactured.

Figure: Pneumatic PTFE-lined plug valve.

Hydraulic PTFE-lined plug valve

This is the PTFE-lined plug valve that is operated by use of a hydraulic actuator. This hydraulic actuator employs hydraulic fluid to generate mechanical energy in terms of torque. The hydraulic actuator is connected to the valve plug via the stem. Hydraulic PTFE-lined plug valve manufacturers design this valve for use in applications that do not need high levels of hygiene due to contamination associated with hydraulics. On the other hand, this valve is very suitable for use where a lot of torque is needed since the hydraulic fluid property of incompressibility results in a large amount of torque relative to the other valves.

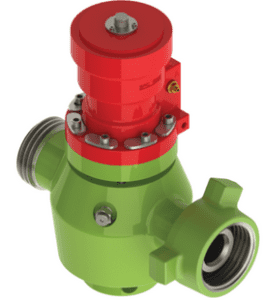

Threaded end PTFE-lined plug valves

This is the type of PTFE-lined plug valve designed with threaded ends. These threaded ends are used to connect the valve to the pipe. PTFE-lined plug valve manufacturers design this type of valve for use in moderate pressure levels but it can be used in a wide range of applications. The valve is designed with male or female threads. If the pipe to be connected has male threads, the valve should have female threads and vice versa.

Figure: Threaded end PTFE-lined plug valve.

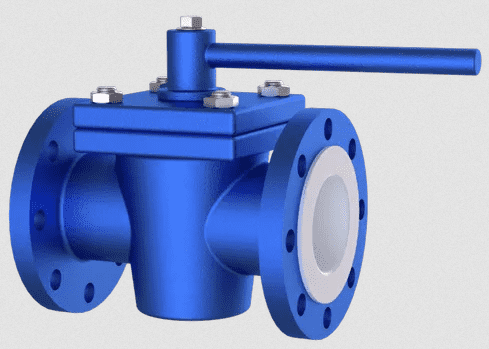

Flanged end PTFE-lined plug valves

This is the type of PTFE-lined plug valve which is connected to the pipe using bolts and nuts. PTFE-lined plug valve manufacturers design this type of valve with flanges on the inlet and outlet ports. The flanges have several holes drilled on them. The purpose of these holes is to hold the bolts used to connect the pipe and the valve. This type of valve is meant for use in high-pressure applications owing to the high torque contributed by each bolt and nut. However, this valve is very heavy relative to other valves like threaded end types due to the many bolts and nuts used as well as the two flanged ends. Also, this type of valve is mostly large and thus it needs large area for installation.

Figure: Flanged end PTFE-lined plug valve.

Applications of PTFE-lined plug valves

- PTFE-lined plug valves are used in chemical processing plants.

- They are used in the manufacturing of fertilizers.

- PTFE-lined plug valves are used in food and beverage processing plants.

- They are used in water supply and waste water treatment.

- They are used in pharmaceutical manufacturing plants.

- PTFE-lined plug valves are used in fluid diversion and mixing.

- They are used in petrochemical industries.

Advantages of PTFE-lined plug valves

- These valves are fast in operation because with only a quarter turn of the handle the valve will open or close.

- PTFE-lined plug valves are free from fluid leakage due to tight seals.

- These valves are cheaper relative to other valves.

- They have long service life compared to the lubricated plug valves.

- PTFE-lined plug valves are easy to install and repair.

- These valves are of compact and simple construction.

- They are easy to clean.

- PTFE-lined plug valves have excellent corrosion resistance.

- They can withstand relatively high pressure and temperature.

- These valves have low resistance to fluid flow when fully open which enhances efficiency.

- PTFE-lined plug valves can be used for on and off as well as throttling applications.

- These valves have few rotating parts which reduce the chances of wear and maintenance costs.

Disadvantages of PTFE-lined plug valves

- These valves have extreme pressure drop when used in throttling applications. PTFE-lined plug valve manufacturers recommend these valves for throttling use only if the flow process has a low-pressure drop.

- Large valves cannot be operated via the handle due to large torque required so an actuator has to be used.

Troubleshooting PTFE-lined plug valves

Leakage through the valve stem

- Worn out or damaged gland packing. Replace the gland packing.

- Damaged stem. Replace the stem.

Leakage through the valve body and pipe connection

- Worn out gasket. Replace the gasket.

- Excess fluid pressure. Reduce the fluid pressure to ensure the valve is operating at the pressure recommended by the PTFE-lined plug valve manufacturer.

- Loose connection. Tighten the connecting elements.

The handle is hard to operate

- Damaged stem. Replace stem.

- Foreign materials clogged between the stem and body cover. Open the valve according to the instructions given by the PTFE-lined plug valve manufacturer and clean off the materials.

Summary

PTFE-lined plug valves are plug valves that have the internal part covered with PTFE material. Due to the use of this PTFE material the valve becomes very resistant to corrosion as well as being able to withstand high pressure and high temperature. This type of valve is in the category of quarter-turn valves. This is because PTFE-lined plug valve manufacturers design the valve such that it only needs a quarter turn of the handle to open or close the fluid flow. This valve is operated using a handle or by use of actuators such as hydraulic, pneumatic, and electric actuators. PTFE-lined plug valve manufacturers design this valve for on and off applications as well as throttling fluid flow. However, for throttling, this valve results in a lot of pressure drop and thus it should only be used if the piping system has very low-pressure drop.

Various types of this valve include three-way PTFE-lined plug valves, threaded end PTFE-lined plug valves, flanged end PTFE-lined plug valves, pneumatic PTFE-lined plug valves, hydraulic PTFE-line plug valves, and electric PTFE-lined plug valves among others. The areas of applications of this valve include pharmaceuticals, foods and beverages, chemical processing, sewage treatment, water supply, and petrochemicals among others. The advantages of using this valve are resistance to corrosion, fast operation, low initial cost, low-pressure drop, low maintenance, easy installation, cleaning and repair, and zero leakage.