Sleeved Plug Valve

Sleeved Plug Valve

NTGD is professional sleeved plug valve manufacturer, Don’t hesitate to contact us if you have any inquiry.

What is a sleeved plug valve?

This is a non-lubricated type of plug valve that uses a sleeve component installed around the valve plug to maintain a continuous seal. The sleeve is used to provide the lubricity needed for the plug to rotate smoothly resulting in fast opening and closing of fluid flow. Sleeved plug valve manufacturers also use this sleeve to help reduce frequent maintenance needed in the lubricated type of valves as well as give the valve long service life. Sleeved plug valves are quarter valves. This is because they operate by turning the valve plug for a 90o degree angle to open or close. This type of valve operates manually or by use of actuators. Sleeved plug valves are designed such that the plug moves up slightly when opening fluid flow to ensure it leaves some clearance with the valve seat to avoid wear which can reduce service life of the plug. This type of valve has a tight shut-off and is used in various industrial applications such as waste water treatment, food processing, chemical processing, oil and gas among others.

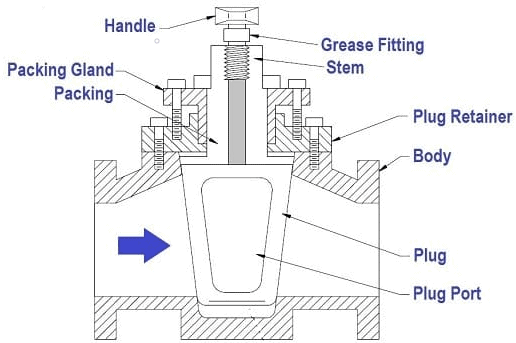

Components of a sleeved plug valve

Handwheel/hand lever

The handwheel or hand lever in a sleeved plug valve is where torque is applied by the valve operator to start or stop the valve. The handwheel/ hand lever is used in manual valves. For an automatic sleeved plug valve, an actuator is used to provide the torque needed to start and stop fluid flow through the valve.

Valve body

This is part of a sleeved plug valve used to house internal parts of the valve. Sleeved plug valve manufacturers make the body from strong metallic materials like stainless steel, ductile iron, brass, bronze among others. The high strength of the materials ensures this valve is very strong against high pressure as well as impact damage that may result from falling objects.

Body cover

This is a component placed on top of the valve body. The cover and body are connected firmly by use of bolts and nuts. The body and cover are made of the same metallic material. The body cover also helps to house internal parts such as seals that prevent fluid leakage via the stem.

Stem

The stem is used in sleeved plug valves to connect the handwheel/actuator to the valve plug. The stem helps to transmit the torque applied on the handwheel/actuator to make the plug move vertically to stop or start fluid flow.

Plug

The plug is the main component of sleeved plug valve and its use is to open and close fluid flow. Sleeved plug valve manufacturers design the plug with a hole or more than one hole at its center. It is through this hole that the fluid flows when the valve is started.

Seat

The seat is a component mounted on the valve body to provide the resting surface for the plug when it closes fluid flow. The seat helps to ensure no fluid leakage when the valve is closed. Sleeved plug valve manufacturers make the seat from different materials such as plastics and rubber.

Gasket

The gasket is placed between the valve body and the body cover to prevent fluid leakage. It is also placed between the body and the pipe connection to prevent any leakage.

Gland packing

This is a type of seal placed between the body and the stem to prevent fluid leakage through the stem.

Sleeve

This is a compressible component placed between the plug and the valve body to ensure smooth rotation of the plug without wear and prevent any leakage.

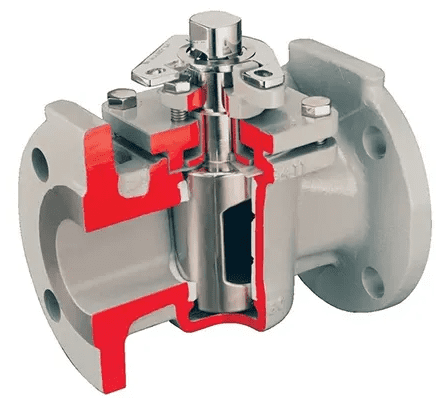

How does a sleeved plug valve work?

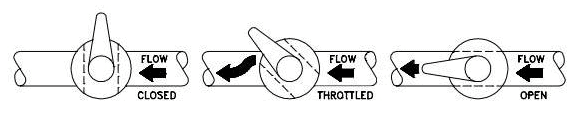

This valve operates by using a handwheel/hand lever or by use of an actuator. Whether the valve is manual or automatic, the working mechanism is the same. The valve starts when the handwheel/ actuator rotates forcing the stem as well as the valve plug to rotate. To open the valve, the handwheel/actuator rotates the valve stem for a quarter turn in the clockwise direction. The rotation of the stem in the clockwise direction forces the valve plug to rotate for a 90o degree where it aligns the plug port collinear to the valve port. This creates an unobstructed path for the fluid to flow through the sleeved plug valve. To close the fluid flow, the handwheel/actuator rotates in the counterclockwise direction for a quarter turn. This then forces the stem and thus the plug to make the same 90o degree turn which positions the plug port normal to the valve port. This ensures the valve plug is blocking the fluid flow and thus no fluid can flow through the sleeved plug valve. For throttling fluid flow, the handwheel is rotated for an angle of around 45o degrees to allow some space for the fluid to flow through the valve. Sleeved plug valve manufacturers recommend use of this valve in throttling fluid flow where pressure drop will not cause technical challenges since throttling causes pressure drop by a great margin.

Types of sleeved plug valves

Three-way sleeved plug valve

This is a sleeved plug valve designed with three valve ports. Sleeved plug valve manufacturers design this valve to help reduce the cost of buying three gate valves for the same task. With this type of valve, one can transport fluid in different lines as well as use the same valve to divert or mix the fluid. When used to mix fluid, the valve gets fluid from two pipes and mixes the two fluids to leave the valve as one fluid stream. For diversion of fluid, one fluid stream enters the valve and the valve port changes its direction of flow to an angle of 90o degrees. This type of valve makes the cost of the piping system cheaper relative to using several gate valves.

Figure: Multi-port sleeved plug valve.

Threaded end sleeved plug valve

This is a sleeved plug valve that is connected to the pipe using threads. Sleeved plug valve manufacturers design this type of valve for use in medium-pressure applications. The valve ports are designed with threaded ends. The pipe end to be connected to the valve is also has threads machined on the end. The threads are male and female such that if the valve has female threads the pipe end should have male threads and vice versa. This type of valve is easy to assemble and small in size relative to the bolted type.

Figure: Threaded end sleeved plug valve.

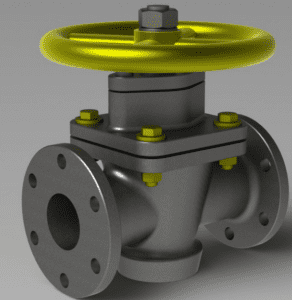

Flanged end-sleeved plug valve

This is a sleeved plug valve that is connected to the pipe using bolts and nuts. Sleeved plug valve manufacturers design this valve with flanged ends on the exit and outlet ports. These flanged ends also have holes drilled on them. The pipe to be connected to the sleeved plug valve also has flanged ends and holes drilled on it. The flanged ends on the valve and pipe are equal. This type of valve is suitable for use in high-pressure applications as it ensures no fluid leakage due to high torque strength enhanced by several bolts and nuts used. The problem associated with this type of valve is that it is usually heavy relative to the welded end and threaded end valve types due to the several bolts and nuts used to tighten it. Also, this valve is large relative to other valves and thus it occupies large area when installed.

Figure: Flanged end sleeved plug valve.

Welded end sleeved plug valve

This is a sleeved plug valve that is connected to the pipe by through welding method. This valve is very reliable as it ensures that no fluid can leak through the valve body-pipe connection due to loose bolts or screw threads. The valve port end and the pipe ends are welded together creating a solid connection free from any flaws that may lead to leakage. Such a valve is suitable for use in applications that involve very hazardous and corrosive media which, in case of any slight leakage may lead to damage to the environment or injury to the valve personnel. The weld has to be removed first before removing this valve from the piping system for repairs.

Applications of sleeved plug valve

- They are used in the oil and gas industry.

- A Sleeved plug valve is used in fluid mixing and diversion.

- They are used in the manufacturing of various types of chemicals due to high resistance to corrosion.

- Sleeved plug valves are used in the manufacturing of fertilizers.

- They are used in municipal water supply and waste water treatment.

- These valves are used in food and beverage processing plants.

- This valve is used in the mining industry as it can control the flow of sludge and slurries.

Advantages of sleeved plug valves

- Sleeved plug valves are very durable relative to the lubricated valve types.

- These valves are not prone to frequent maintenance common in the lubricated valve types.

- Sleeved plug valves are cheaper relative to other valves like gate valves.

- These valves are free from fluid leakage.

- Sleeved plug valves can be used in various applications as they are highly versatile.

- These valves can withstand high fluid pressure.

- Sleeved plug valves are easy to install, clean and repair.

- The design of these valves is simple and compact.

- Sleeved plug valves need a quarter turn to either close or open which makes the operation very fast.

- These valves have low-pressure drop which improve pumping efficiency.

Disadvantages of sleeved plug valves

- Sleeved plug valves are not suitable for throttling use where there is a high-pressure drop.

- Large-sized sleeved plug valves are hard to operate manually.

- Sleeved plug valves cannot be used in high-temperature applications because the sleeve would be damaged.

Troubleshooting sleeved plug valve

Leakage through the stem

- Damaged gland packing. Replace the gland packing.

- Damaged stem. Replace the stem.

- Excess fluid pressure. Ensure the valve is operating at the pressure recommended by the sleeved plug valve manufacturer.

Leakage through the valve body and pipe connection

- Damaged or worn-out gasket. Replace the gasket.

- Loose connection between the body and the pipe. Tighten the connecting elements to attain the torque stated by the sleeved plug valve manufacturer.

- Excess fluid pressure. Reduce the fluid pressure or use a valve with higher operating pressure.

The valve is hard to operate

- Materials are clogged between the stem and the body. Open the valve according to the instructions given by the sleeved plug valve manufacturer and remove the materials.

- The stem has bent. Replace or repair the stem.

- Excess line pressure. Ensure the valve is used at the recommended fluid pressure.

Summary

A Sleeved plug valve is a type of plug valve that uses a sleeve between the body and the plug. The sleeve is used to enhance smooth rotation of the plug without causing wear. This valve is very durable relative to the lubricated one and it can last for years without being replaced. Sleeved plug valve manufacturers design this valve for use with a manual handwheel or by use of actuators. This valve operates by making a quarter turn of the handwheel. This forces the valve plug to rotate aligning its plug port collinear to the valve port. As such, the fluid finds the valve open and thus flows. To close the valve, the handwheel is again rotated in the opposite direction where it aligns the plug port normal to the fluid flow path. This blocks the fluid from flowing through the valve.

Sleeved plug valve manufacturers produce several types of valves such as flanged end-sleeved plug valves, threaded end-sleeved plug valves, welded end-sleeved plug valves, and multiport sleeved plug valves among others. The industries where this valve can be used include chemical processing, pharmaceuticals, foods, and beverages, water supply, mining, oil and gas among others. Advantages of purchasing sleeved plug valves are versatile, fast operation, easy installation, easy repair and cleaning, durable, low cost, zero leakage, and low-pressure drop.