Plug Valve Manufacturer

Plug Valve

The industrial valve business covers a wide range of applications, from water distribution to nuclear power to upstream and downstream oil and gas. Although each of these end-user sectors uses certain basic kinds of valves, the specifics of construction and materials are often quite diverse. One of the most simple, economical, and user-friendly valves available in the market is the Plug Valves.

The purpose of this valve is to stop, start and regulate the flow of fluids by creating a partial or full obstruction in the path of flow. Sometimes the quick and frequent start-stop flow of fluids is desired in certain operations, and Plug valves are best suited for such operations.

In this post, we will learn about plug valves, their kinds, how they function, their distinctive characteristics, limitations, a selection guide, and a broad range of applications to help you choose the right type of valve for your needs.

REQUEST A QUOTE FOR MORE DETAILS

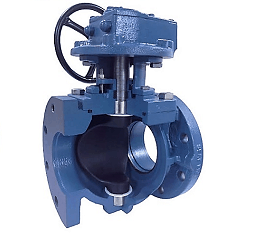

What Is A Plug Valve?

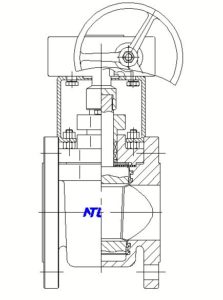

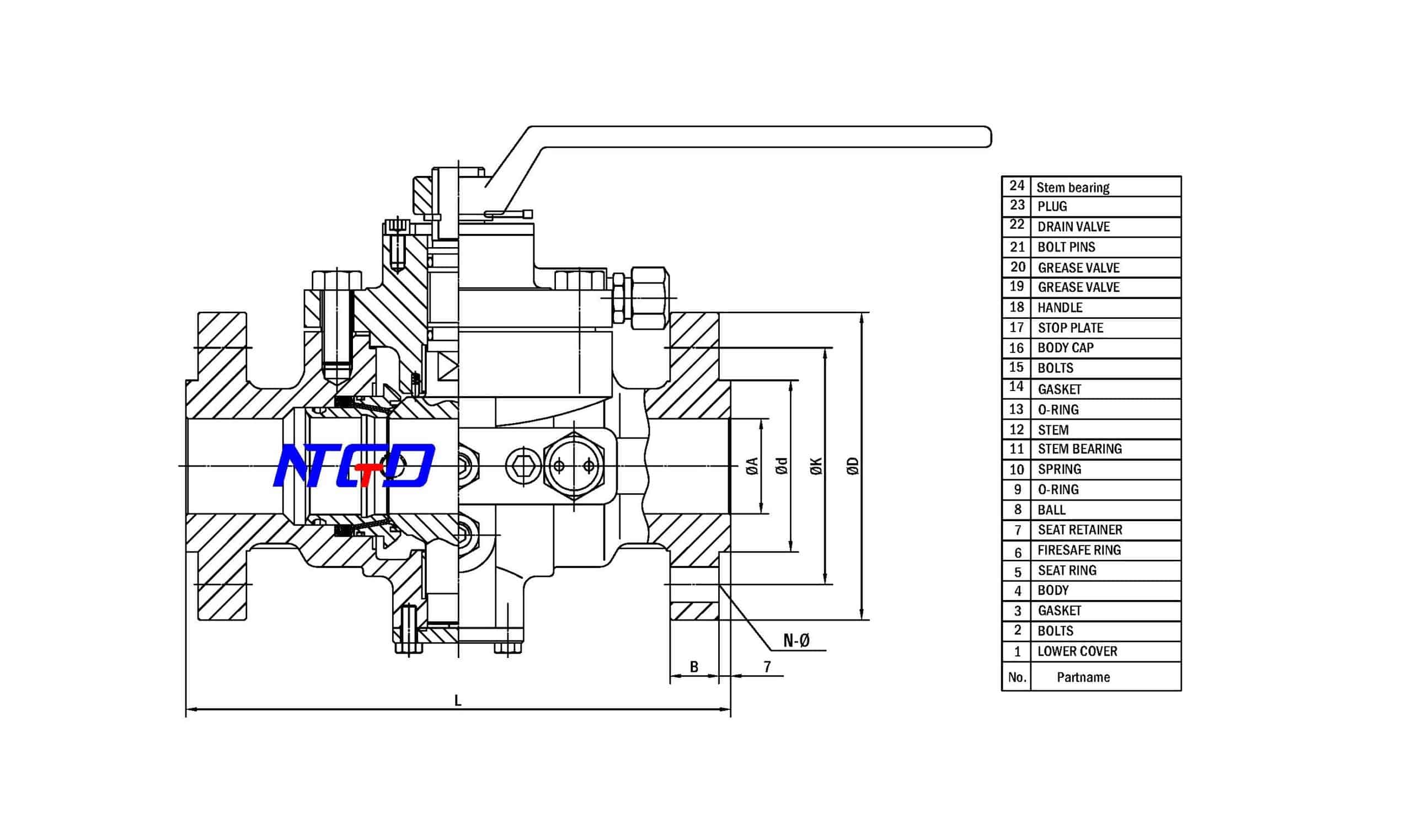

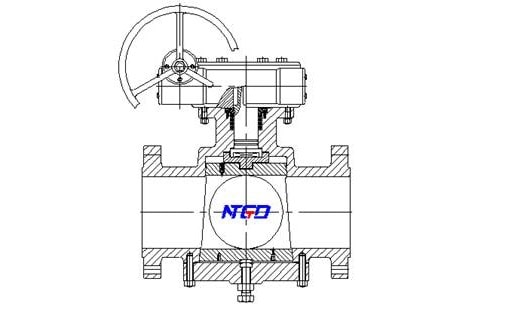

As the name suggests, a plug valve uses a cylinder or tapered plug that can be rotated at a right angle inside the valve body to control the flow of fluids. The plug may have one or multiple passages often placed horizontally to allow ease of flow.

The most common type is the two-port type valve which has a single passage.

How Does The Plug Valve Work?

Plug valves are used where full or no flow of fluid is required. This is achieved by a quarter-turn movement of the valve handle located at the top of the valve. This rotates the cone or cylinder plug in the valve at an angle of 90 degrees in a plane parallel to the plane of the handle movement. This movement will either fully open or block the passage of flow. Thus, full or no flow condition is achieved.

Remember, this type of valve is rarely used to regulate the flow of fluids under pressure as it erodes the edges of the cylinder or cone plug, which leads to poor sealing of the valve. As a result, the valve may become loose and provide insufficient sealing, especially in the case of a multi-port type valve.

Types Of Plug Valve

Lubricated Plug Valve

Non-lubricated plug valve

Eccentric Plug valve

Expanding plug valve.

Multi-port plug valve

Lubricated Plug Valve

Plug valves are generally of all-metal type construction. The narrow gap around the plug and the housing can allow leakage. If the gap is reduced by shrink fitting the plugin the body, it will result in a considerable increase in operational torque. As a solution to this situation, a number of grooves are made around the body and plug where grease is applied through passageways to ease up the motion and seal the gaps between the plug and the body. This type of valve is termed as lubricated plug valves.

These valves can be as big as 24 inches and may handle pressure up to 6000 psi. They are generally made up of cast iron and steel and are able to withstand considerably high temperatures than the non-lubricated plug valves. This type of valve performs well in processes that carry mild abrasive particles such as gas pipe stations, blowdown valves, etc.

Non-lubricated Plug Valve

This type of valve has a polymer sleeve against the body cavity of the plug. The plug acts as a wedge and presses the polymer against the body cavity to reduce friction and provide ease of movement. Non-lubricated plug valves find their application where Maintenance is to be kept at a minimum.

These are also used where the fluid or chemicals flowing have a tendency to get trapped and potentially jam the valve. Non-lubricated plug valve nonmetallic parts are susceptible to damage on exposure to high temperature and corrosive chemicals.

Further, there are three types of non-lubricated plug valve:

- Lift-type plug valve

- Elastomer sleeved plug valve

- Fully lined plug valve

Eccentric Plug Valve

This type of valve uses a half plug which has a high seating force with minimum friction for open and close positions. In addition, an eccentric plug valve demonstrates superior shut-off capabilities. Eccentric valves have a variety of uses in flow control and isolation application, such as sewage pipes, sludge, slurries, grits, etc.

Expanding Plug Valve

These are valves superior design plug valves that use many components that allow the valve to mechanically expand in place during operation and provide a double block and bleed function in a single valve.

These valves use a mechanism that makes the valve swing between the open and closed positions and protects both the seals from the flow path. It ensures no contact between the body and the seal in the closed position to avoid causing any wear or abrasion in the seals.

They are often used to prevent product contamination in applications where double isolation is not required.

Multiport Plug Valve

Three-way plug valves are very common, with a third port typically at a right angle from the inlet. With the three-way design, the closure element is used to divert or combine the flow. Similarly, customized design of four ports, five ports can also be achieved.

Multi-port Plug Valves are of two types:

- Diverting Flow

The fluid enters through the inlet port and passes through the plug, having an inbuilt passage that diverts the flow to one of the two outlets. When the plug is turned 90°, the flow is directed outward to the other outlet. If the plug is positioned midway, the flow will be equally divided to both outlets.

- Combining Flow

This is the exact opposite of diverting flow wherein flow from two inlets enters the valve, passes through the plug, and channels to forms one outlet.

Advantages and Disadvantages of Plug Valve

Advantages Of Plug Valve

- Now let us have a look at the advantages which make Plug Valves different from other industrial valves.

- Simple design with a one-piece, top entry body of the plug and few parts makes it easy to use and maintain.

- Ease of operation with minimum force applied. It can meet a long-term service requirement under a high-temperature environment up to 300 degrees.

- Easy and in-situ Maintenance and repairs possible. All parts are one piece cast-off in this type of valve except the top flange and the cylindrical or taper plug.

- They have a low resistance to the flow of fluid.

- Also, these valves can be customized as per the user’s requirements with various designs available and can be made into two, three, or multi-port units.

- Reliable leak proofing is achieved. The cover seal plug valve can achieve a 1-3mm gap between the body and the plug, which makes it suitable for harsh media like fluids containing catalytic particles, highly viscous, etc.

Disadvantages Of Plug Valve

Plug valves also have some limitations, such as

- They cannot be used for throttling. This is because the lining material exposed to the flowing medium will reduce the PTFE liner’s swelling, which damages the valve.

- DN 100 and larger valves require a gearbox or an actuator larger than that of the ball valve.

- Plug valve transition narrows flows due to conical plug.

- The cost of installing these valves is higher than that of the ball valve, but in the long run, they are more economical because of their high reliability and less maintenance cost.

Where Are Plug Valves Used?

- These valves efficiently handle gas and liquid fuel, so they find a wide variety of use in petroleum, gas, power plants, and the marine industry. They can handle working temperatures up to 300o C, like in the case of boiler feed water, condensate, etc.

- Since it can withstand control and regulate the flow of fluids with suspended solids like sewage, sludge, etc., it is greatly used in the Chemical industry and sewage, sanitation fittings.

- They are widely used in AC and Refrigeration plants, especially the HVAC, to control and regulate the flow of refrigerants. 2 ports, 3 ports, or multi-port valves are especially used in this type of application.

- Commonly used in low pressure and/or low-temperature services, some high pressure and/or high-temperature designs too exist. Thus, it finds a wide variety of usage in different pharmaceutical, food processing, and beverage industries.

Plug Valve Selection Guide

Plug valves are very versatile and find usage in a wide variety of applications. Generally, they can be selected based on the following criteria:

- Purpose: Quick and frequent start-stop requires the usage of these valves. However, this type of valve is not recommended for throttling or flow regulation.

- Medium, Pressure, and Temperature: The nature, pressure, and temperature of the medium govern the selection of the material for these valves.

- Connection fitting at inlet and outlet: This determines what type of inlet and outlet design of the valve is required for the fitting.

- Nature of flow (convergent, divergent, or unidirectional): It specifies the number of inlets and outlet ports required for the application.

- Type of actuation required. (Manual or automatic). Manual actuation involves a simple lever or a gearbox and wheel arrangement. Automatic actuation may be pneumatic or hydraulic.

How To Install A Plug Valve

The pipeline where the installation is to be carried out shall be empty, clean, and pressure-free prior to commencement of installation. The following steps are to be carried out during the installation of a plug valve.

1.Check both inlet and outlet side clean and obstruction-free for correct installation of the valve.

2.Carefully unpack the valve and dismantle the actuating mechanism for ease of installation. It can be put back in place once the installation is complete.

3. Put the valve in place and align it properly, so the faces of the connection meet parallel to each other and are on the same axis without stressing the pipeline.

4. Do not overstress the valve by excessively tightening the flange bolts or coupling. Instead, optimum tightening should be carried out to prevent any leakage from the connections during operation.

5. After installation, make the line operational and check for the proper function of the valve and any leakage in the connection. Tight accordingly.

Additional Tips For Installation

● When this valve is installed in a horizontal line, the preferred installation uses the plug rotating 90° upward to open. Utilizing this orientation can lessen the effect of solids in fluid preventing plug operation.

● In low pressure/low flow systems with solids present, install a valve with the flow against the plug face. (Especially in the case of eccentric plug valve) for extended life.

● When installed in high-pressure systems, it is recommended to have the plug seat on the outlet side of the valve. They may be installed vertically; however, whenever possible horizontal orientation is preferred.

● When installed in a vertical line where solids exist, the seat is ideally positioned up, preventing solid build-up in the valve body.

Maintenance Of Plug Valve

Plug valve does not require any routine maintenance (except in lubricated type plug valves that require routine lubrication) to perform reliably and efficiently. The maintenance of these valves is very simple and can be done in place. With one-piece construction of the valve body and top entry flange of the plug make it easy to use and maintain.

As a precaution, the valve should be isolated, depressurized, and marked properly before the commencement of any maintenance activity.

Let us now go through a basic step-by-step maintenance procedure.

- Remove the bolts holding the actuator housing in place and remove the actuator from the valve.

- Remove the bonnet cover bolts and slowly lift the bonnet flange.

- The plug, PTFE thrust washers, journal bearings, and bonnet stem seals are now accessible and can be removed, checked, and replaced if necessary.

- Using internal snap ring pliers, the snap ring and thrust washer can easily be removed, and condition checked.

- Now the “U” seal is accessible and can be replaced if necessary.

Note: The assembly can be done in exact reverse order of dismantling after Maintenance is carried out.

Summary

We have shared a brief knowledge about the plug valves, their construction, operation, and maintenance, along with some other important facts related to this valve. If you’re reading this, we’d like to thank you and hope you find the information included in the article helpful.

Please get in touch with us if you need any more information regarding the article. You can also leave a comment and express your point of view with us.