Tapered Plug Valve

Tapered Plug Valve

NTGD is professional tapered plug valve manufacturer, Don’t hesitate to contact us if you have any inquiry.

What is a tapered plug valve?

A tapered plug valve is a type of plug valve which uses a tapered plug. Tapered plug valve manufacturers design the plug with one or more tapered ports. This valve operates by rotating the valve plug for 90o degrees to control fluid flow. The fluid flows through the valve via the tapered holes on the valve plug. Tapered plug valves are very fast in operation since with only a quarter turn of the plug fluid can be blocked or allowed to flow through the valve. Tapered plug valves are of simple design and their cost is relatively lower compared to other valves. These valves can be operated by use of a manual handle or by using actuators. The actuators that can be used with these valves include electric, pneumatic and hydraulic actuators.

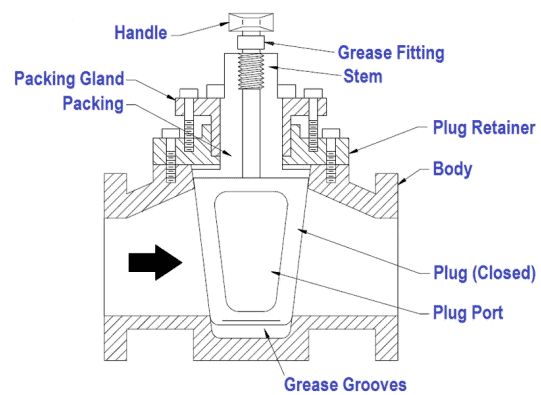

Components of a tapered plug valve

Handwheel

The handwheel or hand lever in a tapered plug valve is the part on which the valve operator holds to apply torque on the valve to open or close the fluid flow. This component is used in manually operated valves.

Actuator

The actuator is a component used on automatically or semi-automatically operated valves. The work of the actuator is to provide the automation and torque that is needed to operate the valve.

Stem

This is the component of the valve that helps connect the valve plug to the handwheel or actuator. The stem helps to transmit the power needed to operate the valve from the actuator/handwheel to the valve plug. Tapered plug valve manufacturers machine the stem from high-strength materials such as carbon steel and stainless steel to make sure it is strong to withstand the torque needed to operate the valve.

Valve plug

The valve plug is the component that is tasked with opening and closing fluid flow through the valve. The plug is powered by a handwheel/actuator via the stem.

Seat

The seat is a component inside the tapered plug valve that provides a seal against the valve plug when the valve is closed. The seat can be made from different materials such as metallic, plastics, thermoplastic, or rubber. The type of material is very important as its properties determine where the valve can be used such as at high temperatures or in corrosive media.

Valve body

The valve body is the component that contains the internal parts of the valve such as the seat, seals, and plug. Tapered plug valve manufacturers make the body using strong materials like stainless steel and carbon steel to ensure it is strong enough to protect internal parts against impact damage and high temperature and pressure.

Body cover

The body cover is a component mounted on top of the valve body. The two are connected using bolts and nuts. The body cover helps to prevent the entrance of dirt into the valve body as well as house seals that prevent fluid leakage through the stem.

Gasket

The gasket is used to prevent fluid leakage between the valve and the pipe as well as between the cover and the valve body.

How does a tapered plug valve work?

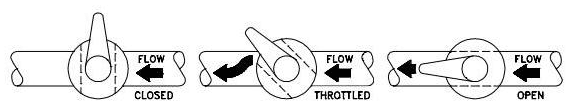

A tapered plug valve operates by rotating the handwheel for manual valves. For automatic valves, an actuator operates the valve by rotating the stem. To open the valve, the handwheel is rotated in the clockwise direction. This rotation is transmitted by the valve stem to the valve plug. As such, the plug makes a quarter-turn rotation in the clockwise direction. Due to this rotation, the plug port becomes aligned to the valve port. As such, the valve becomes free and fluid starts flowing. To close the valve, the handwheel is rotated in the anticlockwise direction. This rotary motion from the handwheel is transmitted to the valve plug via the stem. This forces the plug port to rotate to be normal to the valve port blocking fluid flow. In this state, the valve is said to be closed.

This valve is also used in throttling fluid flow. In this case, the plug is rotated slightly for an angle of around 45o degrees depending on the amount of flow rate needed. However, tapered plug valve manufacturers approve this valve for throttling use only if the piping system has a low-pressure drop. This is because when the valve is used for throttling, the pressure drop becomes extremely large unlike in other valves.

Types of tapered plug valves

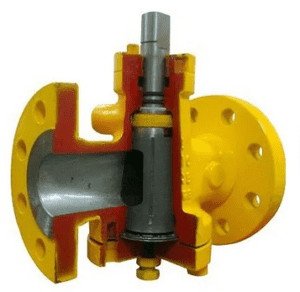

Lubricated tapered plug valves

This is the type of tapered plug valve that uses lubricant. Tapered plug valve manufacturers use lubricant in these valves to make them easier to operate by reducing friction between the plug and the valve body. A layer of lubricant is placed between the plug and the body. The lubricant layer acts as a seal that also prevents fluid leakage. This valve has to be lubricated regularly as recommended by the tapered plug valve manufacturer to enhance its service life. The lubricant used in this valve must also be able to withstand the fluid temperature as well as the media being transported. As such, the lubricant medium used should have chemical resistance, high resilience, and be able to maintain a waterproof seal around the valve body. The chemical resistance property helps to keep the valve and plug safe from corrosion. This type of valve can be used over a wide range of operating pressures and temperatures.

Figure: Lubricated tapered plug valve.

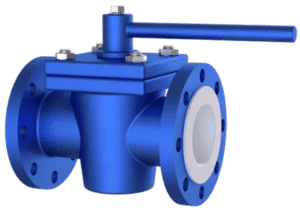

Non-lubricated tapered plug valve

This is the type of tapered plug valve which does not need to be lubricated. This type of valve is mostly used in applications that do not need a lot of pressure. Tapered plug valve manufacturers design this valve with a body sleeve or liner made from elastomers or thermoplastics such as PTFE. The liner or sleeve is mounted in the valve body cavity. As such, the plug compresses the sleeve against the body. This design helps to reduce friction between the plug and the valve body when the plug rotates. Tapered plug valve manufacturers use liners made from materials that are slippery making the valve suitable for use without lubricant film. This is advantageous compared to the lubricated type since it does not need regular maintenance and thus it helps to reduce maintenance costs. If you need to avoid regular maintenance of your tapered plug valve then the non-lubricated type is the best choice.

Figure: Non-lubricated tapered plug valve.

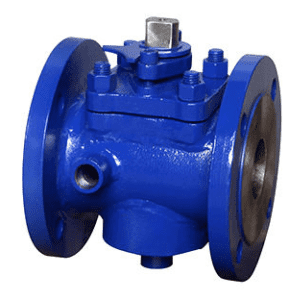

Multi-port tapered plug valve

This is the tapered plug valve which has more than two ports. This type of valve is meant for use in applications that need mixing or diversion of the fluid. For fluid mixing, two or three fluid streams enter the valve and they get mixed inside the valve body. After they are mixed, they form one fluid stream that exits the valve via the outlet port. When the valve is used in fluid diversion one fluid stream enters the valve via the inlet port. The fluid direction of flow is then changed inside the valve body at an angle of around 90o degrees. This design helps to cut down the cost of buying three or four gate valves to do the same task.

Figure: Multi-port tapered plug valve.

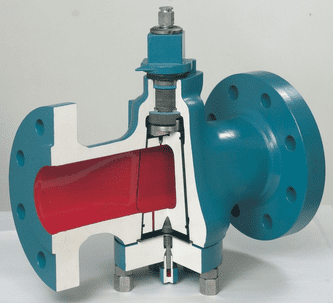

Jacketed tapered plug valves

This is a tapered plug valve that is designed with heating jackets. The heating jackets contain a hot fluid such as oil or steam. This heating media is used to provide heat to the fluid flowing through the valve to ensure its viscosity does not increase or it does not crystallize. Tapered plug valve manufacturers design this valve for use in applications that handle highly viscous fluids such as sulfur, coal tar, peanut, and bitumen among others.

Figure: Jacketed tapered plug valve.

Factors to consider when selecting/purchasing a tapered plug valve

- Fluid viscosity. Very viscous fluid may not work in a valve without heating jackets. Consult the tapered plug valve manufacturer or other valve experts to know if your application needs a jacketed valve.

- Fluid pressure. Excessive pressure may cause fluid leakage.

- Fluid temperature. For high temperatures, the valve seats and internal parts need to be made of metallic materials. For low temperatures, valve internal parts can be made of plastic or rubber.

- Type of media. For fluid that is very corrosive, the valve needs to be made of corrosion-resistant material like plastics or thermoplastics. For non-corrosive media, either plastic, rubber, or metallic material can work. However, consider the cheapest and most reliable option.

Applications of tapered plug valves

- These valves are used in mining applications.

- They are used in chemical manufacturing plants.

- Tapered plug valves are used in water supply and wastewater treatment.

- These valves are used in the foods and beverage industries.

- They are used in oil refineries.

- Tapered plug valves are used in the transportation of highly viscous media such as bitumen and coal tar.

- They are used to control flow of natural gas.

- Tapered plug valves are used in the heating, ventilation, and air conditioning (HVAC) systems.

- They are used in power plants to control flow of steam and water used to run steam turbines.

Advantages of tapered plug valves

- Tapered plug valves are bi-directional. This property makes the fluid flow in either direction of the tapered plug valve.

- They are versatile as they are used in almost all manufacturing and processing industries.

- These valves are free from leakage and of high strength.

- Tapered plug valve construction is simple and compact.

- They are easy to clean and repair.

- Tapered plug valves are resistant to corrosion.

- These valves are of lower cost relative to other valves.

- Tapered plug valves operate very fast since the plug needs a quarter turn to operate.

- These valves can be operated manually or automatically.

- They are used for throttling.

Disadvantages of tapered plug valves

- Tapered plug valves produce a lot of pressure drop when used for throttling.

- The tapered shape of the plug causes pressure drop.

- Large valves cannot be operated manually and thus the need for an actuator.

Troubleshooting tapered plug valves

Fluid leakage through the valve stem

- Damaged or worn-out seals. Replace the seals.

- Damaged stem. Replace the stem.

Leakage through the body-pipe connection

- Worn out or damaged gasket. Replace the gasket.

- Excess fluid pressure. Reduce the flow pressure or use a higher-rated tapered plug valve.

- Loose connection. Tighten the connecting bolts and nuts to the torque recommended by the tapered plug valve manufacturer.

Leakage between the seat and valve plug

- Worn out seat. Replace the seat.

- Worn out seat ring. Replace the ring.

The handle is hard to operate

- Foreign materials clogged between the stem and the cover. Open the valve according to the procedure given by the tapered plug valve manufacturer and remove the materials.

- The stem is damaged. Repair or replace it.

- Excess flow pressure. Reduce the flow pressure.

Summary

A tapered plug valve is a valve that uses a plug that has a tapered shape. Tapered plug valve manufacturers produce this valve from various materials making it suitable for use in wide pressure and temperature levels. This valve operates by turning the tapered plug for a quarter turn to start or stop fluid flow. The clockwise direction of rotation of the handle or actuator opens the valve while counterclockwise rotation closes the valve. This valve can be lubricated or non-lubricated. The lubricated type uses lubricant film between the plug and the body. The non-lubricated type uses a sleeve or liner between the body and the plug to reduce friction and thus wear on the plug.

Tapered plug valve manufacturers produce different types of valves such as lubricated tapered plug valves, non-lubricated tapered plug valves, multi-port tapered plug valves, and jacketed tapered plug valves among others. Applications of these valves include water supply, mining, oil refinery, foods and beverages, chemical processing, and steam plants, among others. The advantages of purchasing a tapered plug valve are fast operation, versatility, high strength, leakage proof, easy installation, repair, and cleaning.